General Properties of Rubber

| General Name | Natural Rubber | SBR | EPDM | Neoprene | CSM | Nitrile | HNBR | Butyl | Silicone | Florocarbon | Florosilikone | Acrylic | Vamak | Epiclorhydrine |

| Chemical | Polyisoprene | Styrene Butadiene Rubber | Ethylene Propilene Rubber | Chloroprene Rubber | Hypalon Rubber | Acrylonitrile Butadien Rubber | Hidrogenated Nitrile Rubber | Butyl Rubber | Silicone Rubber | Florocarbon Rubber | Florosilicone Rubber | Polyacrylic Rubber | Ethylene Acrylic Rubber | Epiclorohydrine Rubber |

| Abbreviation | NR | SBR | EPDM | CR | CSM | NBR | HNBR | IIR | VMQ | FKM | FQ | ACM | AEM | ECO |

| Hardness Range ( IRHD ) | 30 - 95 | 40 - 95 | 30 - 85 | 30 - 90 | 40 - 85 | 40 - 100 | 50 - 95 | 40 - 85 | 40 - 80 | 50 - 95 | 40 - 80 | 50 - 85 | 45 - 90 | 40 - 85 |

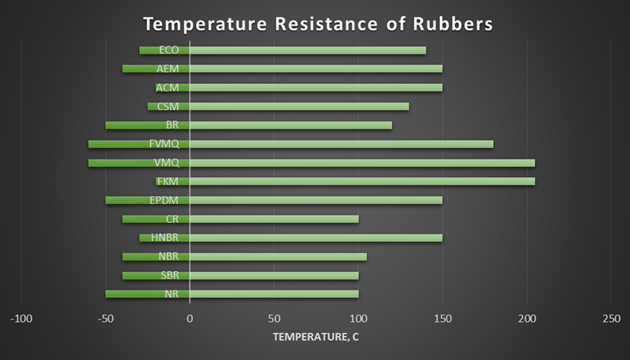

| Service Temperature Range | ||||||||||||||

| Max. | 75 C | 80 C | 130 C | 95 C | 130 C | 100 C | 150 C | 120 C | 205 C | 205 C | 180 C | 150 C | 150 c | 140 C |

| Max. Intermittent | 105 C | 115 C | 150 C | 125 C | 160 C | 130 C | 180 C | 135 C | 300 C | 250 C | 200 C | 180 C | 180 C | 160 C |

| Min. | - 60 C | - 55 C | - 50 C | - 40 C | - 25 C | - 50 C .. - 10 C | - 30 C | - 50 C | - 50 C | - 20 | - 60 C | - 20 C | - 40 C | - 30 C |

| * special types - 80 C | ||||||||||||||

Enviromental Resistance Properties of Rubber

| Polymer | NR | IR | SBR | IIR | BR | EPDM | CR | NBR | HNBR | VMQ | FVMQ | ACM | FKM | ECO |

| Oxidation Resistance | 3-2 | 3-2 | 3-2 | 1 | 3-2 | 2-1 | 2-1 | 3-2 | 1 | 1 | 1 | 1 | 1 | 2-1 |

| Ozone Resistance | 4 | 4 | 4 | 2-1 | 4 | 1 | 2 | 4 | 2-1 | 1 | 1 | 2-1 | 1 | 1 |

| Weathering Resistance | 4 | 4 | 4 | 1 | 4 | 1 | 2 | 3-2 | 2-1 | 1 | 1 | 1 | 1 | 2-1 |

| Sunlight Resistance | 4-3 | 4-3 | 4 | 1 | 4 | 1 | 2-1 | 4-3 | 2-1 | 1 | 1 | 1 | 1 | 2-1 |

| Water Resistance | 1 | 1 | 2-1 | 1 | 1 | 1 | 2 | 2-1 | 1 | 2 | 1 | 4-3 | 2-1 | 2 |

| Flame Resistance | 4 | 4 | 4 | 4 | 4 | 4 | 2 | 4 | 4 | 3-2 | 1 | 4 | 2-1 | 3-2 |

| Heat Resistance | 4 | 4-3 | 3-2 | 2 | 4-3 | 2-1 | 3-2 | 2 | 3-2 | 1 | 1 | 1 | 1 | 2-1 |

| Low Temperature Flexibility | 2-1 | 2 | 2 | 3-2 | 2-1 | 2-1 | 4 | 3-2 | 3-2 | 1 | 1 | 4-3 | 3-2 | 3-2 |

Chemical Resistance Properties of Rubber

| Polymer | NR | IR | SBR | IIR | BR | EPDM | CR | NBR | HNBR | VMQ | FVMQ | ACM | FKM | ECO |

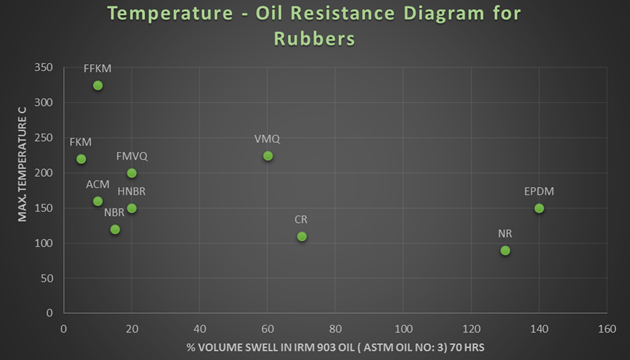

| Oil and Gasoline | 4 | 4 | 4 | 4 | 4 | 4 | 3-2 | 1-2 | 2-1 | 4-3 | 2 | 2 | 1 | 1-2 |

| Animal and Vegetable Oils | 3 | 3 | 3 | 1-2 | 3 | 2 | 2 | 1-2 | 2-1 | 3-2 | 1 | 1-2 | 1 | 1-2 |

| Alcohols | 2 | 2 | 2 | 2 | 2 | 3-2 | 1-2 | 3-2 | 2-1 | 2 | 2-1 | 4 | 3-2 | 2 |

| Alkalies | 3 | 3 | 3 | 1 | 3 | 1-2 | 1 | 1-2 | 1 | 4 | 1 | 4 | 3-2 | 3-2 |

| Acids | 3-2 | 3-2 | 3-2 | 1-2 | 3-2 | 2 | 2 | 2 | 2 | 3 | 1 | 3 | 2 | 4-3 |

| Aliphatic Hydrocarbon Solvents | 4 | 4 | 4 | 4 | 4 | 4 | 2 | 1 | 1 | 4-3 | 1 | 1 | 1 | 1-2 |

| Aromatic Hydrocarbon Solvents | 4 | 4 | 4 | 4 | 4 | 4 | 4-3 | 3-2 | 3-2 | 4-3 | 2-1 | 4-3 | 1 | 2 |

| Oxygenated Solvents | 2 | 2 | 2 | 1-2 | 2 | 1-2 | 4-3 | 4 | 2-1 | 3 | 2 | 4 | 4 | 4-3 |

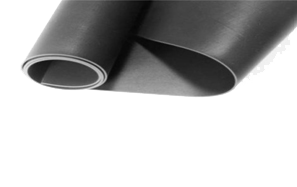

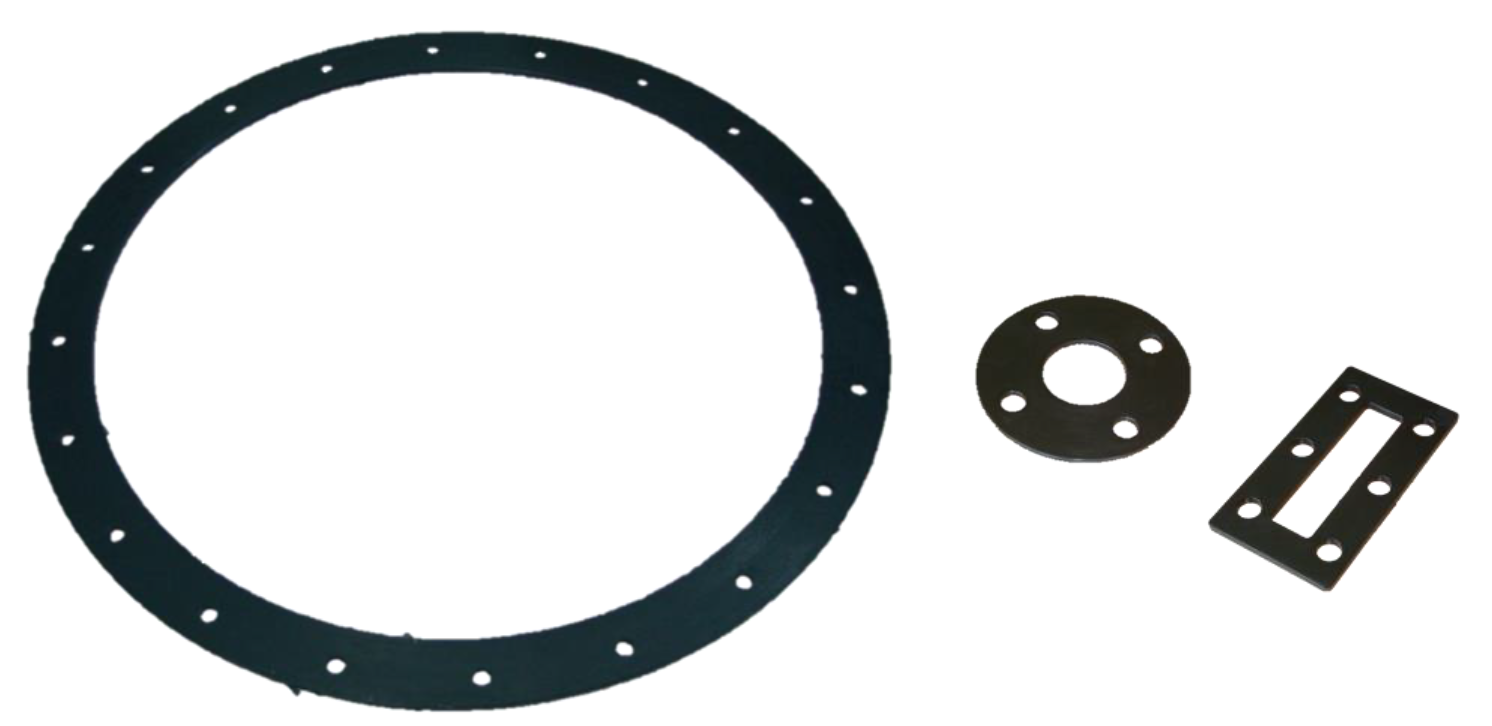

Rubber and Cork Rubber Sheets

Rubber sheets can be manufactured from any type of rubber according to your need of performance. All our NBR, FKM, VMQ, FMVQ, HNBR, CR and Corkrubber sheets are designed as formulation for high performance in transformer industry with our experience of more than 50 years.

| HERSAN STANDARD SHEET SIZES | ||

| Width ( mm ) x Length ( mm ) | Thickness ( mm ) | |

| 540 mm * 540 mm | 2 - 3 - 4 - 5 - 6 - 8 - 10 - 12 | |

| 700 mm * 1000 mm | 2 - 3 - 4 - 5 - 6 - 8 - 10 - 12 | |

| 1000 mm * 1000 mm | 2 - 3 - 4 - 5 - 6 - 8 - 10 - 12 | |

| 1000 mm * 2000 mm | 2 - 3 - 4 - 5 - 6 - 8 - 10 - 12 | |

| 1000 mm * 10.000 mm *** | 2 - 3 - 4 - 5 - 6 - 8 - 10 - 12 | |

| *** for only rubber sheets | ||

| HERSAN 101 | HERSAN 102 | HERSAN 103 | HERSAN 104 | HERSAN 105 | HERSAN 106 | HERSAN 107 | HERSAN 108 | |

| MAX. TEMPERATURE oC | 125 | 125 | 125 | 125 | 125 | 180 | 130 | 130 |

| MİN. TEMPERATURE oC | -30 | -45 | -30 | -35 | -40 | -30 | -60 | -60 |

| HARDNESS Shore A | 70 - 80 | 65 - 75 | 70 - 80 | 70 - 80 | 70 - 80 | 70 - 80 | 70 - 80 | 65 - 70 |

| DENSITY - kg / m3 | 950 | 850 | 1100 | 950 | 1100 | 1100 | 1000 | 1050 |

| RESISTANCE TO MINERAL OILS | 1 | 1 | 1 | 1 | 2 | 1 | 2 | 3 |

| RESISTANCE TO FUEL - GASOLINE | 2 | 2 | 2 | 1 | 2 | 1 | 2 | 3 |

| RESISTANCE TO ALKALI | 2 | 2 | 2 | 2 | 1 | 1 | 2 | 2 |

| RESISTANCE TO UV - OZONE | 2 | 2 | 2 | 2 | 1 | 1 | 1 | 1 |

1 = good 2 = medium 3 = poor

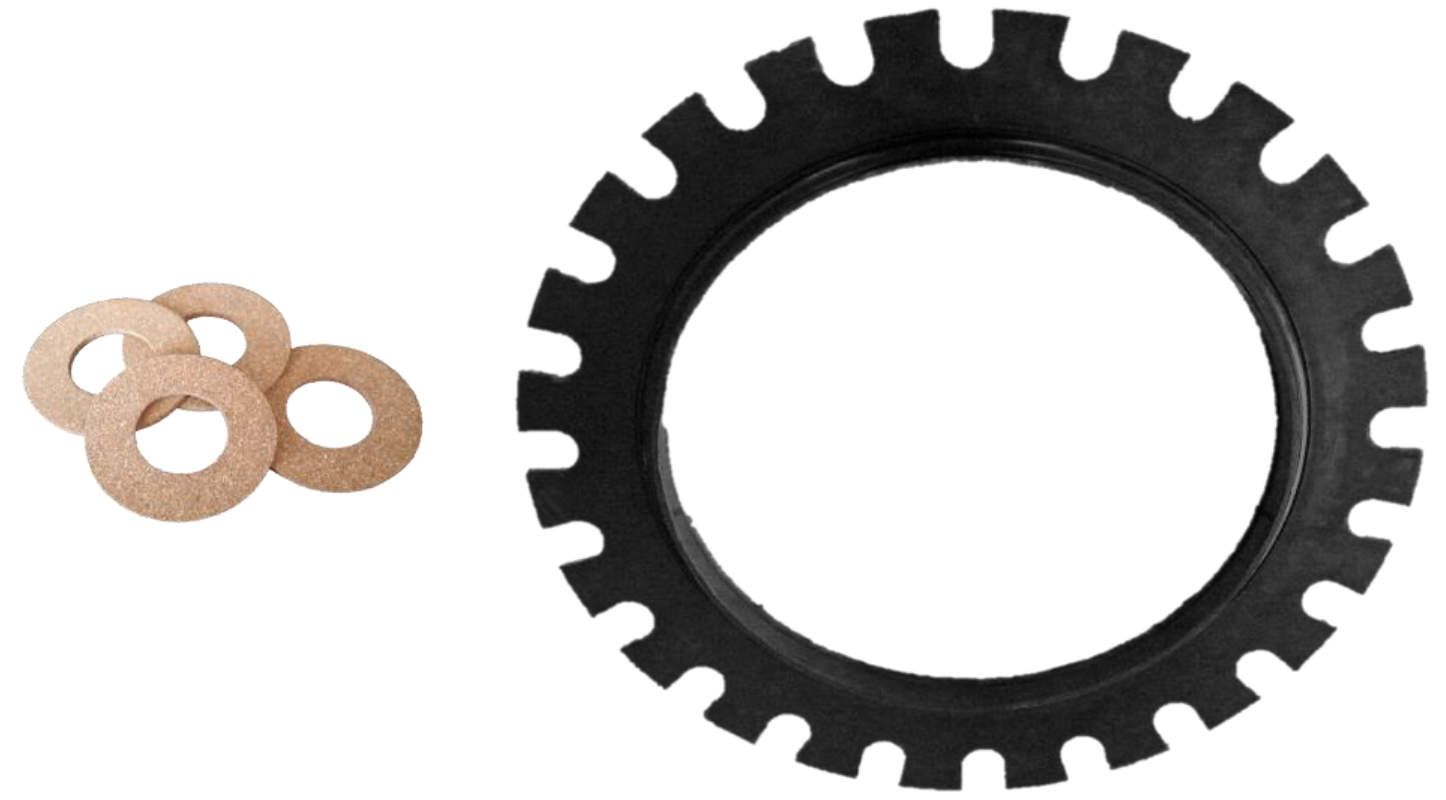

Metric Ropes & Rubber and Corkrubber Strips

Transformer lid rubbers can be manufactured with all types of rubbers as per technical specifications.

Each item can be manufactured with different dimentions on customer request.

Each item can be manufactured with different dimentions on customer request.

| STANDARD METRIC O-RINGS | |

| Φ mm | Roll Length ( mt ) |

| 6 mm | 50 |

| 8 mm | 50 |

| 10 mm | 50 |

| 12 mm | 50 |

| 14 mm | 50 |

| 16 mm | 50 |

| 20 mm | 25 |

| 22 mm | 25 |

| 24 mm | 25 |

| 30 mm | 25 |

| MOST MANUFACTURED SIZES | |

| Φ mm | Roll Length ( mt ) |

| 8 x 12 | 50 |

| 10 x 20 | 25 |

| 12 x 20 | 25 |

| 10 x 25 | 25 |

| 10 x 30 | 25 |

| 20 x 30 | 25 |

| 12 x 40 | 25 |

| 10 x 100 | 10 |

| STANDARD RUBBERCORK STRIP SIZES | ||

| Width ( mm ) | Thickness ( mm ) | Roll Length ( mt ) |

| 30 mm | 4 - 6 | 10 |

| 40 mm | 4 - 6 | 10 |

| 50 mm | 4 - 6 | 10 |

| 60 mm | 4 - 6 | 10 |

| 65 mm | 4 | 10 |

| 70 mm | 6 | 10 |

| 80 mm | 6 - 8 - 10 | 10 |

| 100 mm | 6 - 8 - 10 | 10 |